-

Image gallery: Watch video

-

Model overview for green asparagus and cherries

EWK 600 EWK 1200 EWK 1700 Roller shutter door 1 1 1 Water pump 1 1 1 Socket gate valve 2" 3" 3" Dimensions

EWK 600 EWK 1200 EWK 1700 Depth (inside) approx. 1250 mm 1250 mm 1250 mm Width (inside) approx. 1300 mm 2150 mm 2840 mm Height (inside) approx. 1100 mm 1100 mm 1100 mm Depth (outside) approx. 1390 mm 1390 mm 1390 mm Width (outside) approx. 2025 mm 2310 mm 3750 mm Height (outside) approx. 2615 mm 2615 mm 2615 mm Storage capacity

EWK 600 EWK 1200 EWK 1700 Box

approx. 500x300x265 mmapprox. 32 64 80 Box

approx. 600x400x240 mmapprox. 24 40 56 Pallet

approx.

1200x800 mmapprox. 1 2 3 Cooling capacity

EWK 600 EWK 1200 EWK 1700 Using the integrated cooling unit approx. 300 kg/h 650 kg/h 980 kg/h Using the two-fluid circuit system Depending on

the respective cooling unitDepending on

the respective cooling unitDepending on

the respective cooling unitIntegrated cooling unit

as standard cooling system+ + - Two-fluid circuit

as standard cooling system- - + Model overview for white asparagus

EWK 600 EWK 1200 EWK 1700 EWK 3000 EWK 6000 Roller shutter door 2 2 2 2 4 Water pump 1 1 1 2 4 Socket gate valve 2" 2" 3" 3" 6" Dimensions

EWK 600 EWK 1200 EWK 1700 EWK 3000 EWK 6000 Depth (inside) approx. 1250 mm 1250 mm 1250 mm 2500 mm 2500 mm Width (inside) approx. 1300 mm 2150 mm 2840 mm 2840 mm 5840 mm Height (inside) approx. 1480 mm 1480 mm 1480 mm 1880 mm 1880 mm Depth (outside) approx. 1390 mm 1390 mm 1390 mm 2600 mm 2600 mm Width (outside) approx. 2025 mm 2310 mm 3750 mm 3750 mm 6900 mm Height (outside) approx. 2615 mm 2615 mm 2615 mm 3000 mm 3000 mm Storage capacity

EWK 600 EWK 1200 EWK 1700 EWK 3000 EWK 6000 Box

approx. 500x300x265 mmapprox. 40 80 100 270 528 Box

approx. 600x400x240 mmapprox. 30 50 70 224 392 Pallet

approx.

1200x800 mmapprox. 1 2 3 6 14 Cooling capacity

EWK 600 EWK 1200 EWK 1700 EWK 3000 EWK 6000 Using the integrated

cooling unitapprox. 90kg/h 180 kg/h 350 kg/h 450 kg/h 900 kg/h Using the two-fluid

cooling systemDepending on

the respective

cooling unitDepending on

the respective

cooling unitDepending on

the respective

cooling unitDepending on

the respective

cooling unitDepending on

the respective

cooling unitIntegrated cooling unit

as standard cooling system+ + + - - Two-fluid circuit

as standard cooling system- - - + + -

Function / Application:

- Blast and storage chiller for cooling down white asparagus from approx. 22°C to 1°C and storing by a continuous, gentle sprinkling of ice water

- Blast chiller for cooling down green asparagus or cherris from approx. 30°C to 5°C by a continuous, gentle sprinkling of ice water

The cooling time is approx. 3⁄4 minute per °C.

- Blast cold room and ice water basin insulated in stainless steel design

- Double-walled insulation (80 mm PU foam sealant)

- Floor gratings made of GFK (glass fibre reinforced plastic)

- Heat exchanger, simultaneous ice storage

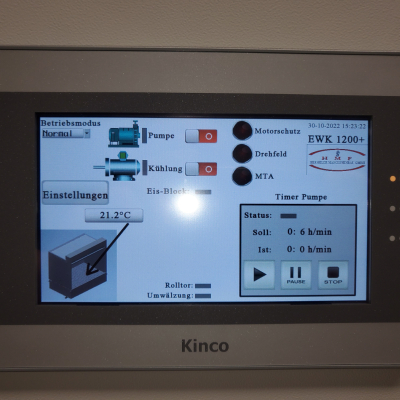

- External control cabinet with temperature display and timer

- Electric roller shutter door (-s) with insulation

- Water pump (-s) for even sprinkling with time interval control

- Sprinkling surface on top, can be swivelled for better cleaning

- Temperature sensor

- Socket gate valve for water drain

- Ready-to-plug-in delivery (400 V)

- Two different cooling systems are possible:

-

Integrated cooling unit, permanently mounted

Connection between cooling unit and chiller is via copper pipes.

Transport of the gaseous refrigerant through the copper pipes -

External cooling unit in a two-fluid circuit

Connection between cooling unit and chiller is via an insulated hose.

A water-glycol mixture runs through the stainless steel pipes of the chiller, if possible in a closed system to reduce temperature loss.

= Waste heat remains outside the building

= Cooling capacity can be adapted to the demand

-

- Adaptation to structural precondition e.g. in-ground blast chiller

= Accessible with pallet truck, etc. - Connection via welded PE pipework instead of a tube when using

the cooling system in a two-fluid circuit - Ice water bassin above the blast cold room (standard: below)

- Step surface with railing above the blast cold room

- UV filter for better disinfection

- Floor gratings made of stainless steel

- Side cleaning flaps

- Programmable logic controller (PLC) for regulating energy consumption when power is supplied via a photovoltaic system (also available as a retrofit kit for existing systems).

- Double function

= Cooling down and storing with only one machine

(concerning white asparagus) - Continuous build-up of an ice storage

- Short cooling time due to circulating ice water

- Individual adjustment of the cooling capacity

- High humidity in the cabinet

= No drying out of the asparagus (white) - No grey fogging

- No watering of the goods to be cooled

= Maintaining quality - No discolourations

= Cherry stem remains green

Individual adaptations in terms of dimensions, capacity, equipment or even other types of fruit and vegetables possible on request.